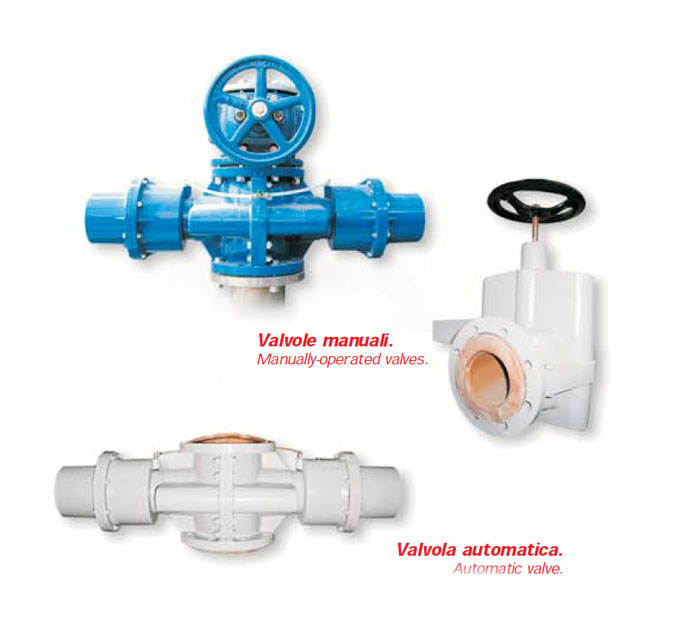

Accessories

Valves

Matec’s silos include a group of high-quality accessories, which improve their performance and guarantee their operation and long life. Automatically- and manually-operated valves for decanter silos, and pipes used for mortar batching in granite gang-saws. The automatically- and manually-operated valves are all coated in a special rubber sheath. The automatic valves can have one or two chambers. The automatic valves are all air-operated.

Pumps

The silo-feeding pumps are essential in order to pump the dirty water from the well into the silo decanter. Matec supples all kind of pumps starting from the ones for the highly corrosive and abrasive liquids to the ones for the clarified water with a capacity range from 100 lt/min to 10.000 lt/min.

Silos

Vertical decanters:

Based on the principle of static decantation and the natural precipitation of suspended solid particles, they speed up the clarification process through perfectly-sized silos, with a thrust cone and a water column which presses the sludge, and the use of an appropriate polyelectrolyte (flocculant). Matec offers the quickest clarification process for any type of wastewater.

Horizontal decanters (scraper bridge):

Ideal for large water flows, they have a limited height and are provided with an upper sludge thickening system. They are operated by a scraper-blade bridge, which pushes the sludge, which settles down to the bottom and is pushed out. The sludge is fed out automatically and the out-feeding operation is adjusted to the bridge effort. The sludge thus condensed can be disposed of into artificial lakes, quickly filtered by the filter press system.

Download Pdf

Complete turnkey systems

Matec designs, manufactures and installs turnkey new installations. Matec provides to customers highly skilled workers and technicians, qualified competence and assistance. Matec has certified its quality system according to UNI EN ISO 9001:2000 and puts great attention to environmental issues and safety, having started the certification process according to the UNI EN ISO 14001 and OHSAS 18001. Moreover, it is in the possession of the Certification of Qualification for the Execution of Public Works, has certified its welding process according to the UNI EN ISO 3834-2, its welding procedures and welders.

The provision of an installation dedicated to the project is the soul that drives Matec to realize complete projects giving its customers not just a machine but an automatic integrated system, fully designed in order to achieve the desired final result: clear water and perfectly pressed mud.

Download Pdf

Filter Presses

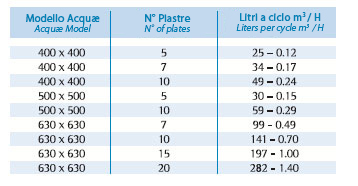

THE ACQUAE RANGE

The perfect solution for middle-size companies and workshops, especially in the marble, granite and ceramic industry, for filtering sludge and wastewater from the washing of truck tyres.

- – All made of single-block steel from thick slabs.

- – Processed with plasma, laser or water-jet technology.

- – Purified water is discharged through 2 external manifolds.

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic system.

- – Automatic panel shaking, for perfect sludge separation, Gasser patented system.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC.

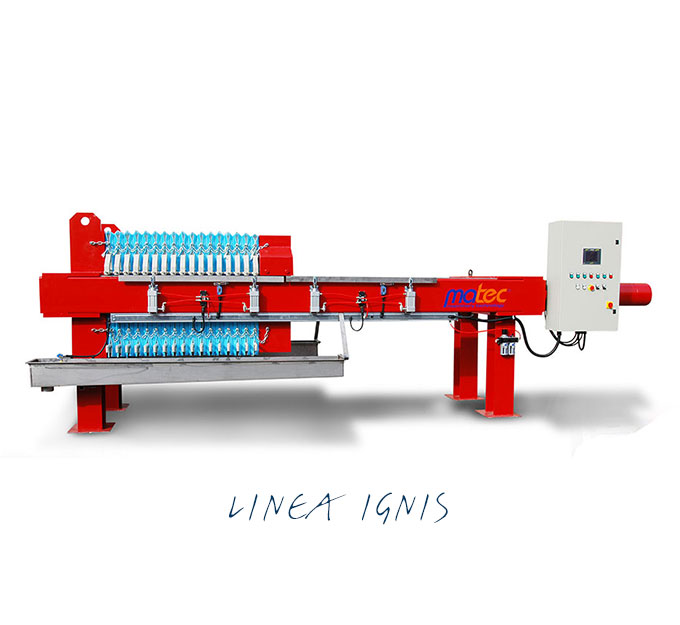

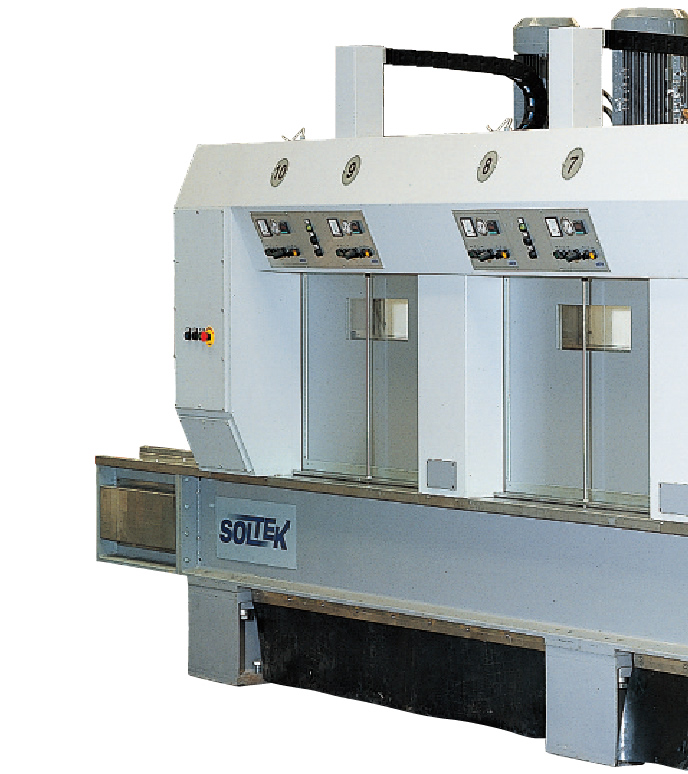

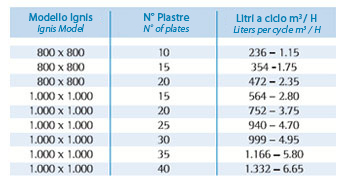

THE IGNIS RANGE

The perfect solution for medium- and large-size workshops for pressing substantial amounts of sludge and for aggregate

quarries having mean sludge concentrations up to 5/6 m3/h.

- – All made of single-block steel from thick slabs.

- – Processed using plasma, laser or water-jet technology.

- – Purified water is discharged through 2 external manifolds.

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic syste.

- – Automatic panel shaking, for perfect sludge separation, Gasser patented system.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC.

- – 400 Bar oil-pressure central unit.

- – Oversize thrust pistons.

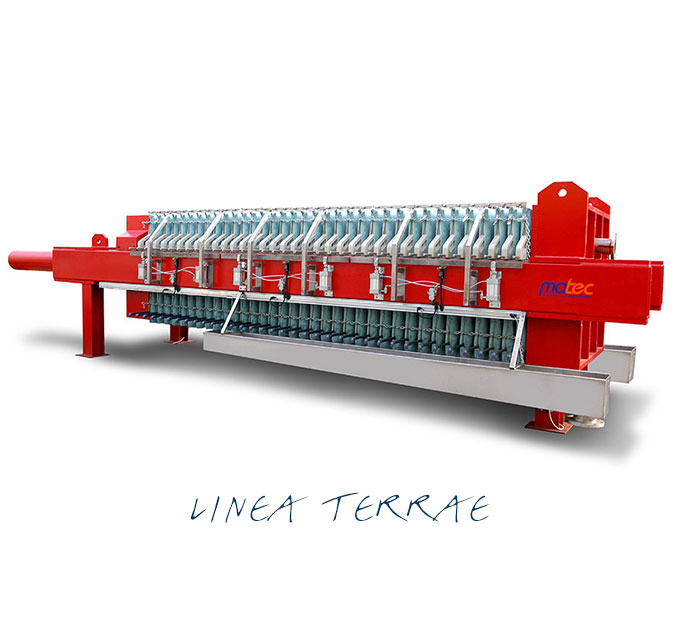

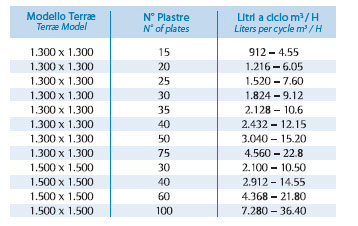

THE TERRAE RANGE

Perfect for large-size production plants specialising in aggregate mining, earth and gravel handling.

- – All made of single-block steel from thick slabs.

- – Processed using plasma, laser or water-jet technology.

- – Purified water is discharged through 4 external manifolds (to prevent external contact or filtrate leaks).

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic system.

- – Automatic panel shaking, for perfect sludge separation.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC

Download Pdf

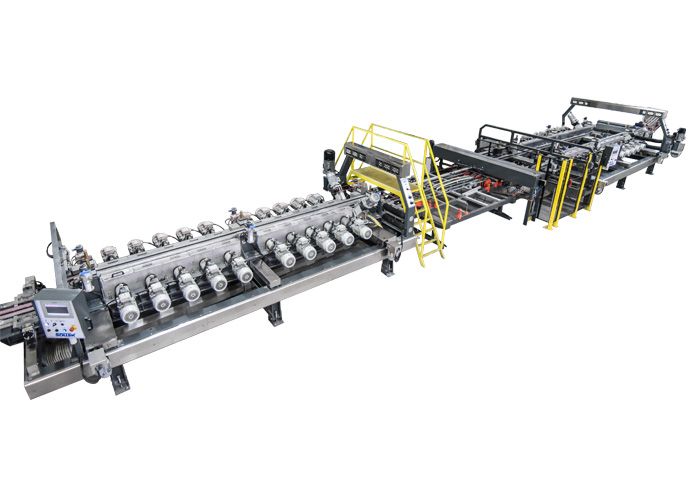

MSB Squaring Machine

Squaring Machine. Ideal for grinding and chamfering tiles in ceramic tiles, single-fired, double fired and third fired.

With its construction features, the MSB is a sturdy machine, made with top quality materials, but above all, it is simple and extremely versatile when it comes to changing formats and to the normal adjustments needed during squaring/chamfering processes.

Download Pdf

“THUNDER” Calibrating Machine

The new calibrating machine manufactured by has been designed to calibrate glazed ceramic tiles of different sizes with no need to change the tools when changing the size of materials. Using PLANA 5-wheel calibrating heads, tiles wide up to 45 cm can be calibrated/faced using a fixed bridge and up to 60 cm using a mobile bridge.

Download Pdf

REFLEX Polishing Machine

REFLEX is designed for processing single fired, double fired, ceramic tiles or third fired tiles with glazed and decorated surfaces.

Using special satellite heads is possible to follow the superficial dips of the tile during processing with a result of uniform polishing without any damage to the glaze and colours of the tile.

Download Pdf

News

Prodotti

Teste Lucidatrici

Teste Calibratrici

Mandrini

News

News

News

MÁQUINAS PULIDORAS

КАЛИБРОВОЧНЫЕ ГОЛОВКИ

Macchine Calibratrici

Macchine Squadratrici

CALIBRATING HEAD

POLISHING HEAD

SPINDLES

POLISHING MACHINES

PRODUCTS

ШПИНДЕЛИ

ПОЛИРОВАЛЬНЫЕ МАШИНЫ

MÁQUINAS ESCUADRADORAS

MÁQUINAS CALIBRADORAS

MANDRILES

CABEZALES CALIBRADORES

Macchine Lucidatrici

CABEZALES PULIDORES

ПОЛИРОВАЛЬНЫЕ ГОЛОВКИ

News

KARELEME MAKİNELERİ

KALİBRASYON MAKİNELERİ

PARLATMA MAKİNELERİ

KESME EĞİRMENİ

News

CİLALAMA BAŞLIĞI

MÁQUINAS RECTIFICADORAS

MÁQUINAS CALIBRADORAS

MÁQUINAS POLIDORAS

News

MANDRIS

CABEÇAS CALIBRADORAS

CABEÇAS POLIDORAS

PRODUCTOS

KALİBRASYON BAŞLIĞI

КАЛИБРОВОЧНЫЕ МАШИНЫ

КРОМКОЗАКРУГЛЯЮЩИЕ МАШИНЫ

抛光磨头

砂轮磨头

主轴

抛光机

砂轮机

磨边机

POLISSEUSES

CALIBREUSES

DÉLIGNEUSES

MANDRINS

TÊTES À CALIBRER

TÊTES À POLIR

Produits