- POLISHING HEAD

- TL 104/105/106 Polishing Head

- TL 155 Polishing Head

- STORM 5 Polishing Head

- HTS Polishing Head

- CALIBRATING HEAD

- “3+3” Calibrating Head

- TS3 Calibrating Head

- MIX Calibrating Head

- DAMP Calibrating Head

- PLANA Calibrating Head

- TEC Calibrating Head

- SPINDLES

- SQS Spindle

- MCS Spindle

- POLISHING MACHINES

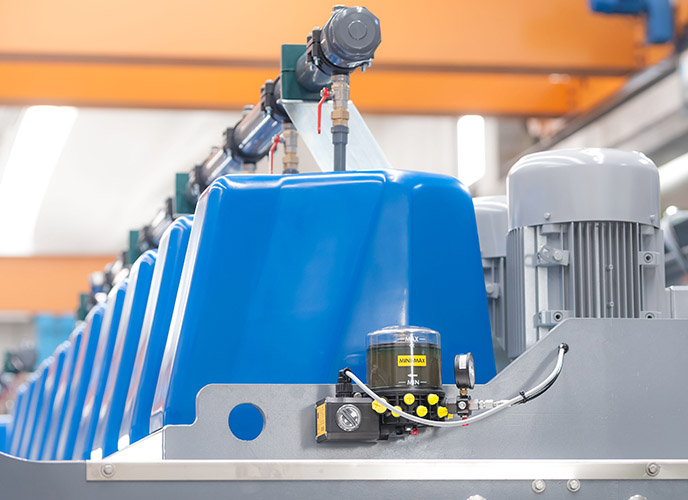

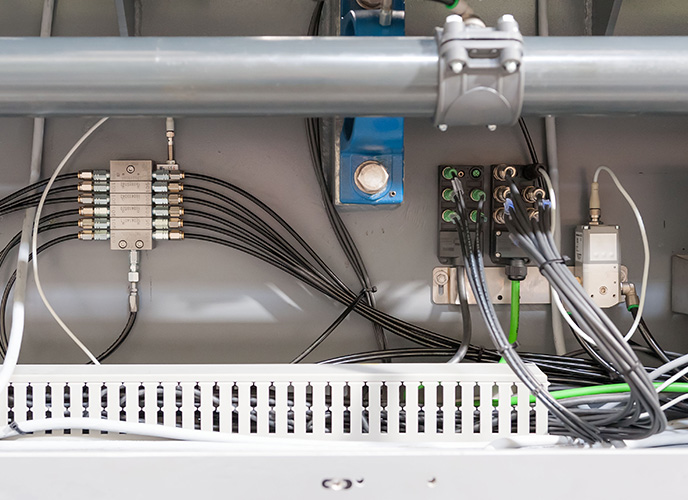

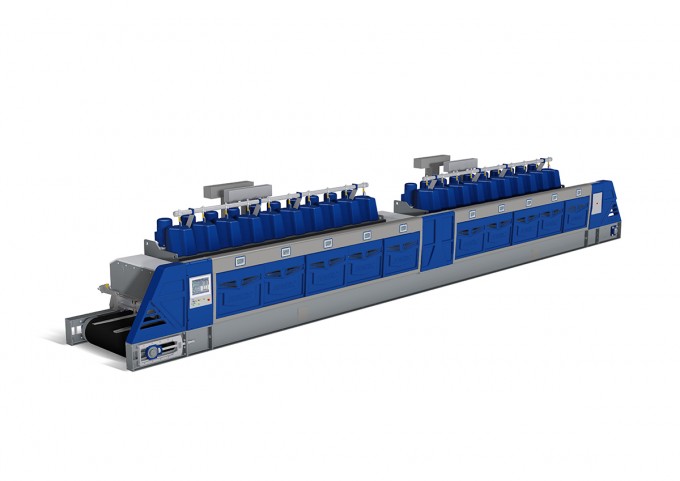

- STORM SERIE LS

- CALIBRATING MACHINES

- SQUARING MACHINES

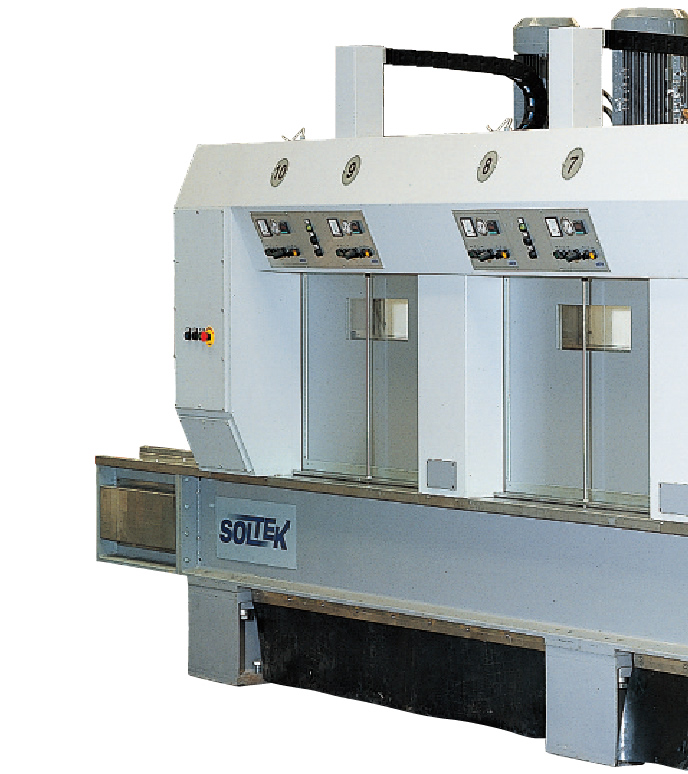

STORM SERIE LS

SOLTEK is a new name and a new reality in the market of processing machinery for ceramic tiles, in particular glazed stoneware tiles.

To be a new name for SOLTEK does not mean to be a newcomer to the ceramic world; SOLTEK is the result of an internal division of one corporate branch of CO.ME.S. srl, that for years has been a leader in the manufacture of polishing and honing heads for ceramics and granite and driving gears.The technical knowledge and the experience gained by CO.ME.S. in over 40 years working in mechanics and in particular in the manufacture of granite and ceramic polishing heads are the starting point of the newly-founded SOLTEK.

The ongoing development of the tile processing industry and the need to offer a more and more accurate and efficient customer service has led CO.ME.S. to develop a new, totally-independent company which totally specialises in the ceramic industry.

Download Pdf

Accessories

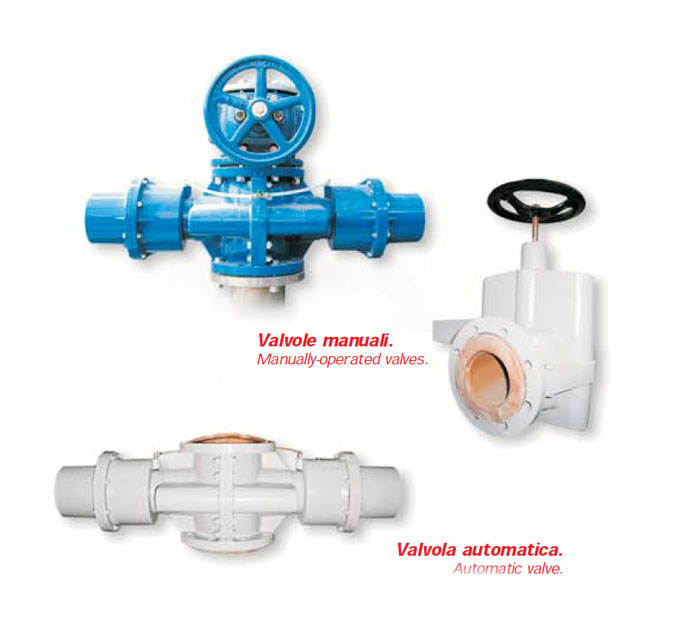

Valves

Matec’s silos include a group of high-quality accessories, which improve their performance and guarantee their operation and long life. Automatically- and manually-operated valves for decanter silos, and pipes used for mortar batching in granite gang-saws. The automatically- and manually-operated valves are all coated in a special rubber sheath. The automatic valves can have one or two chambers. The automatic valves are all air-operated.

Pumps

The silo-feeding pumps are essential in order to pump the dirty water from the well into the silo decanter. Matec supples all kind of pumps starting from the ones for the highly corrosive and abrasive liquids to the ones for the clarified water with a capacity range from 100 lt/min to 10.000 lt/min.

Silos

Vertical decanters:

Based on the principle of static decantation and the natural precipitation of suspended solid particles, they speed up the clarification process through perfectly-sized silos, with a thrust cone and a water column which presses the sludge, and the use of an appropriate polyelectrolyte (flocculant). Matec offers the quickest clarification process for any type of wastewater.

Horizontal decanters (scraper bridge):

Ideal for large water flows, they have a limited height and are provided with an upper sludge thickening system. They are operated by a scraper-blade bridge, which pushes the sludge, which settles down to the bottom and is pushed out. The sludge is fed out automatically and the out-feeding operation is adjusted to the bridge effort. The sludge thus condensed can be disposed of into artificial lakes, quickly filtered by the filter press system.

Download Pdf

Complete turnkey systems

Matec designs, manufactures and installs turnkey new installations. Matec provides to customers highly skilled workers and technicians, qualified competence and assistance. Matec has certified its quality system according to UNI EN ISO 9001:2000 and puts great attention to environmental issues and safety, having started the certification process according to the UNI EN ISO 14001 and OHSAS 18001. Moreover, it is in the possession of the Certification of Qualification for the Execution of Public Works, has certified its welding process according to the UNI EN ISO 3834-2, its welding procedures and welders.

The provision of an installation dedicated to the project is the soul that drives Matec to realize complete projects giving its customers not just a machine but an automatic integrated system, fully designed in order to achieve the desired final result: clear water and perfectly pressed mud.

Download Pdf

Filter Presses

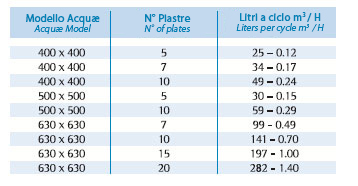

THE ACQUAE RANGE

The perfect solution for middle-size companies and workshops, especially in the marble, granite and ceramic industry, for filtering sludge and wastewater from the washing of truck tyres.

- – All made of single-block steel from thick slabs.

- – Processed with plasma, laser or water-jet technology.

- – Purified water is discharged through 2 external manifolds.

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic system.

- – Automatic panel shaking, for perfect sludge separation, Gasser patented system.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC.

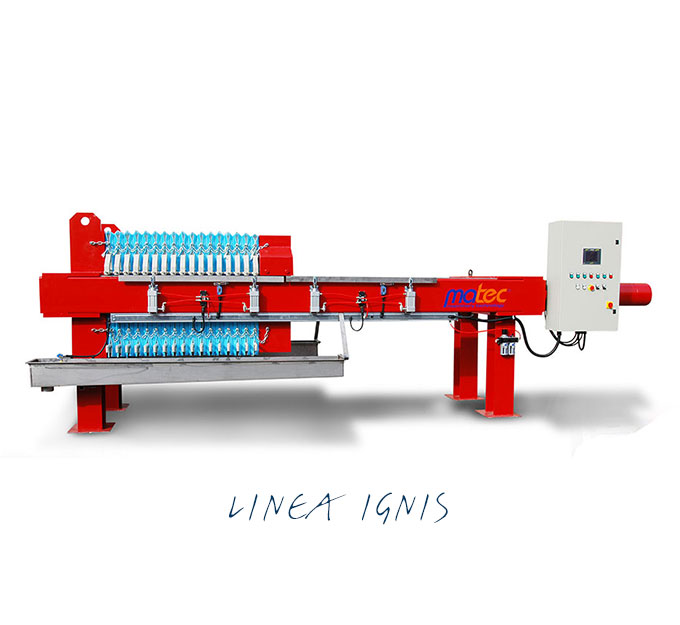

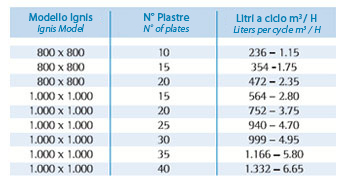

THE IGNIS RANGE

The perfect solution for medium- and large-size workshops for pressing substantial amounts of sludge and for aggregate

quarries having mean sludge concentrations up to 5/6 m3/h.

- – All made of single-block steel from thick slabs.

- – Processed using plasma, laser or water-jet technology.

- – Purified water is discharged through 2 external manifolds.

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic syste.

- – Automatic panel shaking, for perfect sludge separation, Gasser patented system.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC.

- – 400 Bar oil-pressure central unit.

- – Oversize thrust pistons.

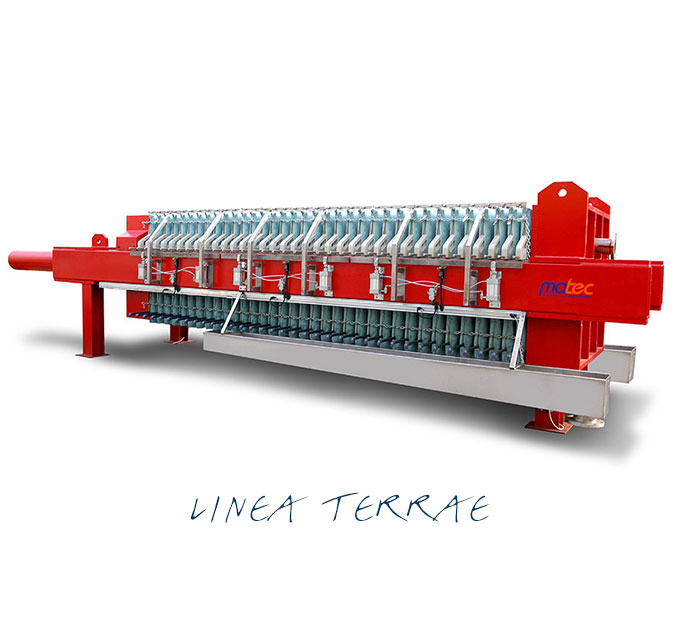

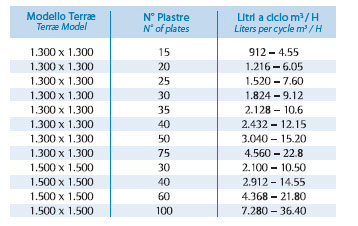

THE TERRAE RANGE

Perfect for large-size production plants specialising in aggregate mining, earth and gravel handling.

- – All made of single-block steel from thick slabs.

- – Processed using plasma, laser or water-jet technology.

- – Purified water is discharged through 4 external manifolds (to prevent external contact or filtrate leaks).

- – First-choice parts by major manufacturers.

- – Stainless steel accessories.

- – High-speed, high-pressure hydraulic system.

- – Automatic panel shaking, for perfect sludge separation.

- – Automatic cloth and plate washing.

- – Electronic control of all system through a PLC

Download Pdf

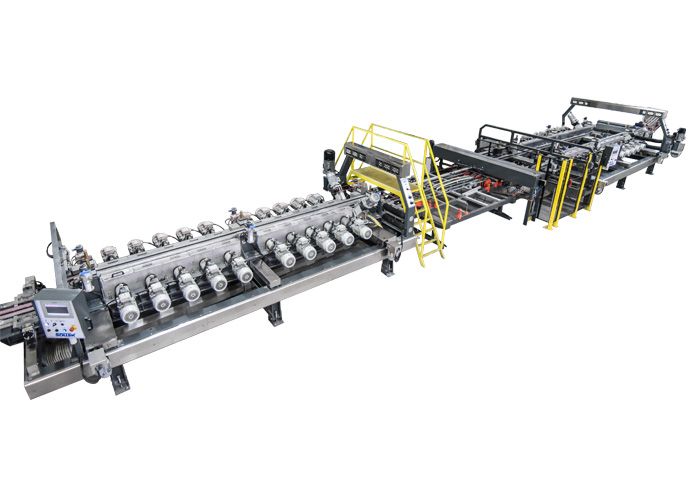

MSB Squaring Machine

Squaring Machine. Ideal for grinding and chamfering tiles in ceramic tiles, single-fired, double fired and third fired.

With its construction features, the MSB is a sturdy machine, made with top quality materials, but above all, it is simple and extremely versatile when it comes to changing formats and to the normal adjustments needed during squaring/chamfering processes.

Download Pdf

“THUNDER” Calibrating Machine

The new calibrating machine manufactured by has been designed to calibrate glazed ceramic tiles of different sizes with no need to change the tools when changing the size of materials. Using PLANA 5-wheel calibrating heads, tiles wide up to 45 cm can be calibrated/faced using a fixed bridge and up to 60 cm using a mobile bridge.

Download Pdf

REFLEX Polishing Machine

REFLEX is designed for processing single fired, double fired, ceramic tiles or third fired tiles with glazed and decorated surfaces.

Using special satellite heads is possible to follow the superficial dips of the tile during processing with a result of uniform polishing without any damage to the glaze and colours of the tile.

Download Pdf

SQS Spindle

SQS is a squaring spindle with a front grindstone, used to grind the sides of any type of tile. Its construction with first-rate materials, highly accurate workmanship and right sizing make this spindle reliable in the long term, accurate in its results and soundproof. The sliding gears, protected by special bellows, and the revolving gears are all soaked in an oil bath, with long-life, heat-proof seals. The SQS spindle can be easily adapted to several types of machines.

Specifications of the SQS

Max power kW 5.5

Stroke mm 75

Max mandrel revolving speed revs/min. 2800

Grindstone max diam. mm 350

Amount of lubricant l 1

Weight with lubricant Kg 35

TS3 Calibrating Head

The TS3 head has been designed to finish granite and ceramic surfaces once gauged by calibrating heads or rolls.

You may even use it as an excellent calibrating head if you add coarse-textured diamond tools.

But it has been specifically designed and developed to finish surfaces that have been gauged by aggressive tools.

As everyone knows, the calibrating process carried out in the first few polishing stations by aggressive tools to remove material or by diamond rolls or radial heads (especially before granite-strip polishing machines or ceramic polishing machines) leaves more or less deep marks, and the surface is not always perfectly gauged and levelled out. That is why the TS3 has been designed to finish and improve the work of the calibrating heads.

The 3 satellites are 200 mm in diameter, with a marked slope, so it can work not on just one point of the satellite (as opposed to the standard satellite calibrating heads with 5 or 6 satellites, 150 mm in diameter) but all across the radius of the tool, which, with its marked slope, will touch up the surface of the material with a large section of the tool (all across the radius) and very powerfully (steep slope). Obviously, any surface marks and flaws are further gauged and levelled out, thus providing a perfect, flawless planar surface, as well as optimising the use of diamond on the next heads, helping save some stations and start off even before using abrasives for the finishing/polishing process. This means more abrasives are used in the finishing process. So, in other words, the TS3 helps improve not only the calibrating results but also the glossy finish of the material.

MIX Calibrating Head

The Mix head is a revolution in the mechanics of polishing heads, as it has 3 satellites and 3 fickert arms that work on the surface all at the same time .

Such mechanism has been designed to solve 2 problems that may occur when polishing granite:

1 – The deep marks left on the surface by the satellite heads in the first few stations of the polishing machines.

2 – The need to use several stations after the calibrating heads, with diamond tools on fickert heads, to the detriment of the finish.

The Mix head, with its 3 satellites and 3 flickert units:

a) remarkably reduces the section of the material, even at zero pressure, thus acting as a veritable calibrating head.

b) its 3 flickert units, despite calibrating at the same time as the satellites, act as limit switches for the satellites, thus removing the marks left by the aggression of the satellite tools and helping achieve excellent levelling results.

c) as a consequence, because the material is so well levelled out and free of any of the usual deep marks, diamond consumption on the next stations is optimised, so fewer flickert TYPE heads need to be used and the material is already finished by the consumable abrasives. Which, of course, adds value to the material.

DAMP Calibrating Head

The DAMP is a special satellite head with 5 or 6 abrasive tools used to hone/lap even tiles of different size. It consists of a revolving casing in spheroid graphite cast iron, equipped with 5 or 6 grindstones which are secured to special corrosion-proof rests. The internal gears, bearings and all other mechanisms are soaked in an oil bath, with long-life, heat-proof seals. The motor drive provides the working force. The fixed flange must only withhold the torque reaction, without having to be rigidly fastened to the machine body. distinctive feature of these heads is the special internal vibration damper system that polishes the tile evenly, even when the surface is particularly bent. In addition, the shafts can be angled away from the axis of rotation of the head, to make it easier for the abrasive grindstone to remove and finish the material during the process. The head should be installed on honing machines provided with a backpressure feature.

Technical specifications of the DAMP

Number of satellites No. 5/6

Max power kW 15

Min head revolving speed revs/min. 400

Max head revolving speed revs/min. 600

Abrasive grindstone max diam. mm 150

Amount of lubricant l 9.3/9.2

Weight with lubricant Kg 100/102

Max honing diameter mm 460

TL 104/105/106 Polishing Head

The TL is a special satellite head with 4, 5 or 6 abrasive tools, used to hone/lap even very small tiles. It consists of an aluminium revolving casing, equipped with 5 grindstones which are secured to special corrosion-proof rests. The internal gears, bearings and all other mechanisms are soaked in an oil bath, with long-life, heat-proof seals. The motor drive provides the working force.

The distinctive feature of these heads is the special internal vibration damper system that polishes the tile evenly, even when the surface is particularly bent. In addition, the special construction of the SOLTEK satellite head produces satin-finished or semi-honed surfaces where the surface dips and bumps are polished and the edges are rounded. The head should be installed on honing machines provided with a backpressure feature.

TL 155 Polishing Head

The TL155 is a special satellite head with 5 abrasive tools, used to hone/lap even very small tiles. It consists of an aluminium revolving casing, equipped with 5 grindstones which are secured to special corrosion-proof rests. The internal gears, bearings and all other mechanisms are soaked in an oil bath, with long-life, heat-proof seals. The motor drive provides the working force. The fixed flange must only withhold the torque reaction, without having to be rigidly fastened to the machine body. The distinctive feature of these heads is the special internal vibration damper system that polishes the tile evenly, even when the surface is particularly bent. In addition, the special construction of the SOLTEK satellite head produces satin-finished or semi-honed surfaces where the surface dips and bumps are polished and the edges are rounded. The head should be installed on honing machines provided with a backpressure feature.

It is very popular for “lappato” processing and “satin” effect.

Specifications of the TL155

Number of satellites No. 5

Max power kW 15

Min head revolving speed revs/min. 400

Max head revolving speed revs/min. 600

Abrasive grindstone max diam. mm 150

Amount of lubricant l 8.7

Weight with lubricant Kg 98

Max honing diameter mm 460

STORM 5 Polishing Head

Polishing head with multipurpose attachment for all kinds and models of multi-head and single-head polishing machines.

They are bought not only by end users but by lots of machine manufacturers all over the world as well.

The main advantages of these heads are:

1) The internal design has much fewer parts than the old heads. Its system (international patent for COMES’ Storm) for driving the swinging arm, using a differently-sloping cogged gear (instead of cams), avoids any clearance that could prevent the arms swinging evenly and consistently in both directions (as opposed to cam-based systems); such accuracy also prevents consumables (diamonds and abrasives) wearing out unevenly, thereby saving money and delivering excellent polishing results.

2) Easy, cheap maintenance. Fewer parts, a simple design and the fact that one half, if not actually just over one half, of them are commercial parts, so they can be found at any retailer or specialist shop all over the world, will save time and money (parts without a code next to the exploded view in the manual are commercial parts).

3) Flexibility and adaptability of the head, even on flawed surfaces once cut (for granite) or once baked (for ceramics) or specially corrugated (for ceramics, special engravings are provided in the moulds). This is because of the 12 heavy-duty steel ‘springs’ (see explodedview, part no. 69) that make the head extremely flexible as well as equally effective and powerful on surfaces that need to be gauged or polished.

4) All mechanical parts are lubricated by just one type of lubricant. They use either grease type 00 or oil, as shown in the list we provide or as written on a table on the head.

HTS Polishing Head

Polishing head with multipurpose attachment for all kinds and models of multi-head and single-head polishing machines.

They are bought not only by end users but by lots of machine manufacturers all over the world as well.

The main advantages of these heads are:

1) The internal design has much fewer parts than the old heads. Its system (international patent for COMES’ Storm) for driving the swinging arm, using a differently-sloping cogged gear (instead of cams), avoids any clearance that could prevent the arms swinging evenly and consistently in both directions (as opposed to cam-based systems); such accuracy also prevents consumables (diamonds and abrasives) wearing out unevenly, thereby saving money and delivering excellent polishing results.

2) Easy, cheap maintenance. Fewer parts, a simple design and the fact that one half, if not actually just over one half, of them are commercial parts, so they can be found at any retailer or specialist shop all over the world, will save time and money (parts without a code next to the exploded view in the manual are commercial parts).

3) Flexibility and adaptability of the head, even on flawed surfaces once cut (for granite) or once baked (for ceramics) or specially corrugated (for ceramics, special engravings are provided in the moulds). This is because of the 12 heavy-duty steel ‘springs’ (see exploded view, part no. 69) that make the head extremely flexible as well as equally effective and powerful on surfaces that need to be gauged or polished.

4) All mechanical parts are lubricated by just one type of lubricant. They use either grease type 00 or oil, as shown in the list we provide or as written on a table on the head.

PLANA Calibrating Head

SOLTEK twenty-year experience in the manufacture of polishing heads has led it to come up with a new-generation calibrating head, the PLANA, which is a trailblazer in the stone processing industry, ideal to calibrate porcelain materials, ceramics, engineered quartz , natural granite and cement.

PLANA’s tools include horizontal-shaft rolls with internal and external holders to prevent any buckling. The size and layout of the rollers form a very small polishing bore so that small sized materials too can be processed. They revolve around their shaft and around the mid-shaft of the head; the rolls and the head guard run at different tangential speeds so the processed surfaces are perfectly level and the calibrating result is better than those of any other calibrating system. As it is a “head”, it can be used on fixed- or mobile-bridge machines, and the size of the processed material can be easily and quickly changed. The guard is made of nodular cast-iron; the gearing is made of high-quality case-hardened steel.

TEC Calibrating Head

TEC is a calibrating head designed to process ceramics, and procelain materials. The tools, which include 6/8 tapered abrasive disks, are held up both inside and outside to prevent any buckling. With their design and their layout on the revolving shaft of the head, they produce perfectly honed surfaces, with no marks left from the rubbing of the tools on the material. Such heads are ideal to remove the marks left by the calibration of the ceramic tile and to prime the material to be polished straightaway, using swinging-arm heads.

MCS Spindle

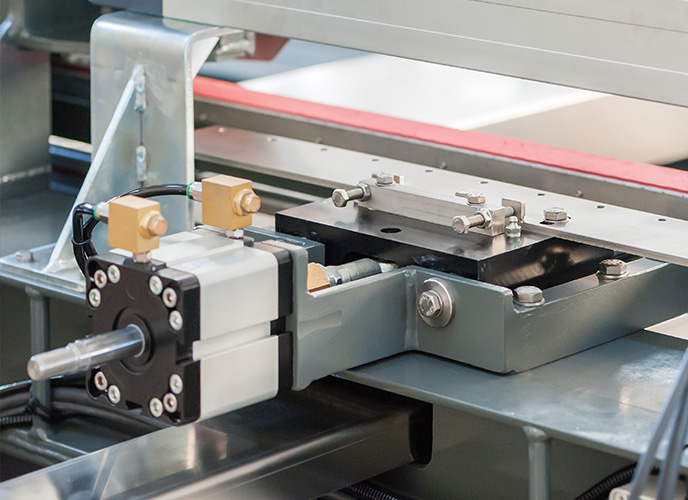

The “MCS” calibrating unit is ideal for calibrating and levelling stone materials, especially porcelainised stoneware and ceramics. The “MCS” spindle, when fitted with the PLANA tapered-roll calibrating head, can be used to process tiles up to 60 cm wide, with no need to change the diamond tool every time the size is changed. The MCS spindle has been designed and developed to go with any available calibrating line in replacement of the horizontal-shaft calibrating rolls. Its difference lies in the fact it can be fitted in the same place as the calibrating roll, using the vertically-sliding rails and the motor reducer which used to operate the roll-holder. In addition, the spindle features a pneumatic system that quickly lifts the calibrating head when the belt stops moving, then such system brings the had gently back on to the material when the working cycle is resumed. The spindle shaft is driven by a belt and pulley system.

“3+3” Calibrating Head

3+3 is a radial head with 6 tool holder shafts where can be fitted abrasive resin diamonds and diamond tools to hone porcelain ceramic and lapato tiles.

It is this two ductile iron crankcase. Gears and internal gears made of special materials heat-treated.

The thrust of work is held by flange motorcycle transmission. The fixed flange to keep only the pair of reaction without being stuck rigidly to rorpo machine.

The key feature of this head is the strength of all components designed to withstand very demanding applications and extreme operating conditions.

3+3 your head allows you to work across a large area of the other heads, with the possibility of changing the operating points from the three external tools.

The 3+3 puts in combined rotation 6 different tools and each of them has a different point of contact, with 6 different contact inclinations with regard to the reference radial that passes through the centre of the tools and the centre of the head.

Therefore there are 6 different working signs, that tend to cross each other and combine rotation and the lateral move of the head system.